Food Grade – strict standards for plastic parts

The production of food requires many different machines. Because of their special requirements for cleanliness and safety, components made from plastic are often used. In using them, as opposed to metal parts for example, external lubrication may not be needed. However, materials and components which come into contact with food must meet strict standards.

The EU Regulation Nr. 10/2011 regulates for example which plastics may be used in food production equipment. It limits the migration value, which is the maximum amount of substances which, under extreme conditions, are allowed to migrate out of the plastic. The US FDA (Food and Drug Administration) also sets high standards. Materials which meet these high standards are "Food Grade".

LiNNOTAM FG – the strong cast polyamide for food

"Food Grade" is a prerequisite for the use of plastic in food production. Additionally, the different applications have different requirements for the materials, such as temperature resistance or load capacity.

Licharz is one of the few suppliers to make robust cast polyamides with special additives which are acceptable for the food industry. All semi-finished LiNNOTAM products which meet the strict standards for food applications are named "FG" for "Food Grade".

Robust plastics for demanding applications

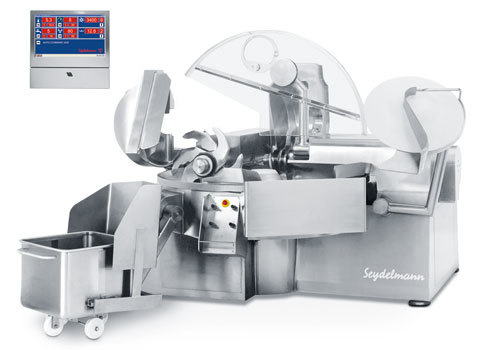

Whether at low temperatures in meat and sausage preparation or at especially high temperatures in the making of baked goods: the cast polyamides LiNNOTAM FG are especially wear resistant and resistant to chemicals. Ejector discs, wear pads, scrapers, rollers, gears or other parts – food grade components can be made for almost every application.

The material LiNNOTAMHiPERFORMANCE FG is used for example for components in special pumps which are used for fluids like mash, drinks and other biochemical substances. LiNNOTAM FG stands up to the high temperatures, is resistant to aggressive foodstuffs, eg. grease, and demonstrates its excellent wear resistance, especially together with stainless steel rotors.

Hydrolytic stability for safety in food processing

LiNNOTAM FG from Licharz fulfils the requirements of the food industry: hydrolytic resistance. Hydrolysis is the splitting of a chemical connection through reaction with water. In order that no plastic particles get into the food, it is extremely important that the plastic is hydrolytic resistant.

The following LiNNOTAM products are ideal for use in food processing:

- LiNNOTAM FG

- LiNNOTAMHiPERFORMANCE HPI FG

- LiNNOTAMHiPERFORMANCE 1200 FG

- LiNNOTAMGLiDE FG

- LiNNOTAMGLiDE PRO T FG

Food Grade for other conventional materials too

In addition to the LiNNOTAM product line, Licharz also offers conventional materials with "Food Grade". Guide tubes for sausage production can be made from POM. Components like feed screw housings in which rotating stainless steel feed screws mesh together are particularly susceptible to wear. Here the especially low friction POM GL is used.

You would like to know which material is the right one for your application? Contact our application engineers!